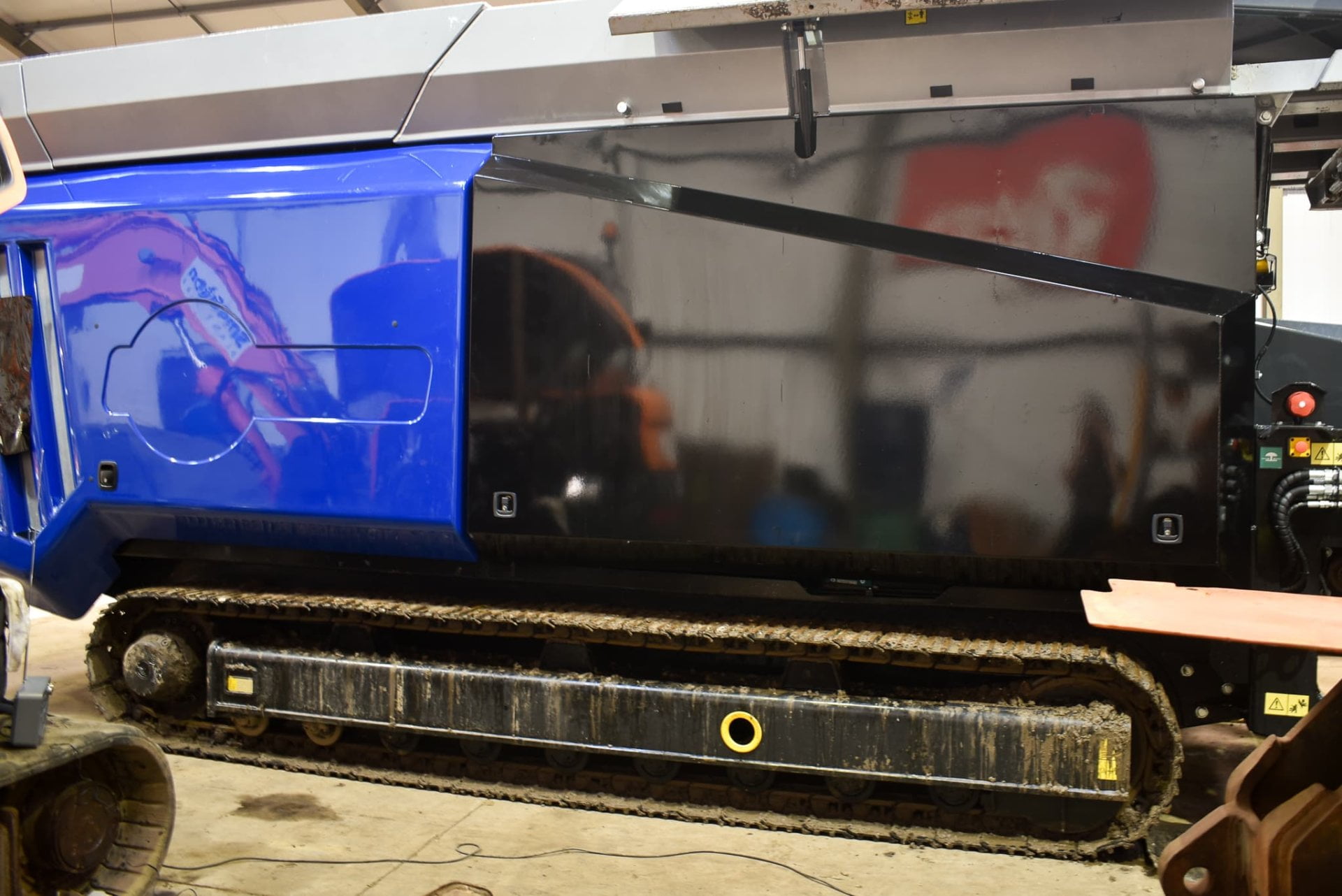

One of the largest vinyl stickers in Dundee.

Waste disposal operators, Patersons Skip Hire are based in Dundee and director, Kerr Paterson continually invests in his business. A waste shredder was purchased to increase the efficiency on the gradually expanding site.

Big bucket loads drop all types of waste products into the top of the shredder. The waste is filtered through huge rotating teeth and then spat out of the back of the machine. The shredder has a hard life in this environment because stray objects can fall from the buckets and damage the sides. Therefore, it’s sensible to protect the panels.

Machines in similar environments are wrapped with transparent vinyl. The wrap protects the panels from scrapes and scratches by reducing the likelihood of damage to the panels. The machine’s resale value is higher, as well as making it easier to refurbish.

Kerr was keen to protect his investment. He had an idea: why not wrap the shredder to look like the rest of his fleet? Kerr thought, who makes big vinyl stickers in Dundee?

Selecting a robust, yet conformable gloss black vinyl would be essential for the project. I sourced a vehicle wrap vinyl which was thick enough for adequate protection and can still be moulded over curved surfaces.

Once wrapped in black, the shredder would mirror the liveries on the rest of the fleet.

The black vinyl is supplied in roll widths of 1520mm. The shredder’s largest panels exceed the roll width size, so planning where the segments of vinyl would be placed helped disguise the overlapped edges of neighbouring vinyl segments.

In total, thirty metres of vinyl was ordered, which was just enough to transform the machine’s factory colour into Patersons black.

The shredder was delivered to Smeaton Plant Hire’s premises on the outskirts of Dundee. Graeme Smeaton kindly leant his large, warm shed for the project. Graeme’s shed provided enough space to cut the large segments of vinyl off of the rolls, as well as ample space to work around the shredder.

In addition to segmenting each piece, I clean as I go. This helps minimise mishaps or overestimate when measuring.

The manufacturer’s decals were also removed before the black vinyl was applied.

The air vents at the back of both sides were tackled first. The vents are too deep and awkwardly shaped for moulding vinyl inside. Portions of vinyl were carefully measured, cut and applied individually to each recessed outlet.

Big vinyl stickers were then positioned on each flat panel before being firmly applied. Each segment was trimmed and heated on all exposed edges. The heating process enables the vinyl to bond securely.

The angled panels near the drop zone are at the most risk of damage. The panels had a double skin of vinyl applied to provide more protection from stray objects dropping into the shredder.

Finally, Paterson’s recognisable livery was applied to both large side panels. Not to mention the manufacturer’s replacement decals. Safety instructions were also secured onto the machine for operatives.

Vehicle graphics are a wise investment for businesses. The shredder’s livery advertises whilst it’s on site, hired out and hauled elsewhere.

The entire application took me alone, approximately twenty five hours over two days. The end result was fantastic. The shredder lives in Kerr’s yard and is hard to miss.

Interested in discussing how your business will benefit from vinyl stickers in Dundee?

Get in touch to find out more.